Briquetting Machines Services

Our purpose is to offer a quality service to our customers as well as to generate new alternatives to the different needs and requirements for the briquetting industry.

We provide a comprehensive service to the entire line that covers the briquette manufacturing process.

We specialize in briquetting roller maintenance, hydrostatic testing, electrochemical machining of segments, replacement of parts, components and maintenance to the entire line of the iron briquette manufacturing process, quality controls and full service onsite or outsite.

Facilities on workshop

Electrochemical machines to machining and re-machining of new or used briquetting segments.

Mobile column boring machine Juaristi MDR-110cm with a table dimension of 9 meter.

Lathe Zerbst DP2500 6m length between centers and 1.5m swing over bed Cap. 30T.

Hydraulic testing bench.

Boring machine Tos Varnsdorf W100a with a table stroke of 3 meters.

Lathe Tos Celakovice Su100 6 meters length between centers and 1-meter swing over bed, Cap. 10T.

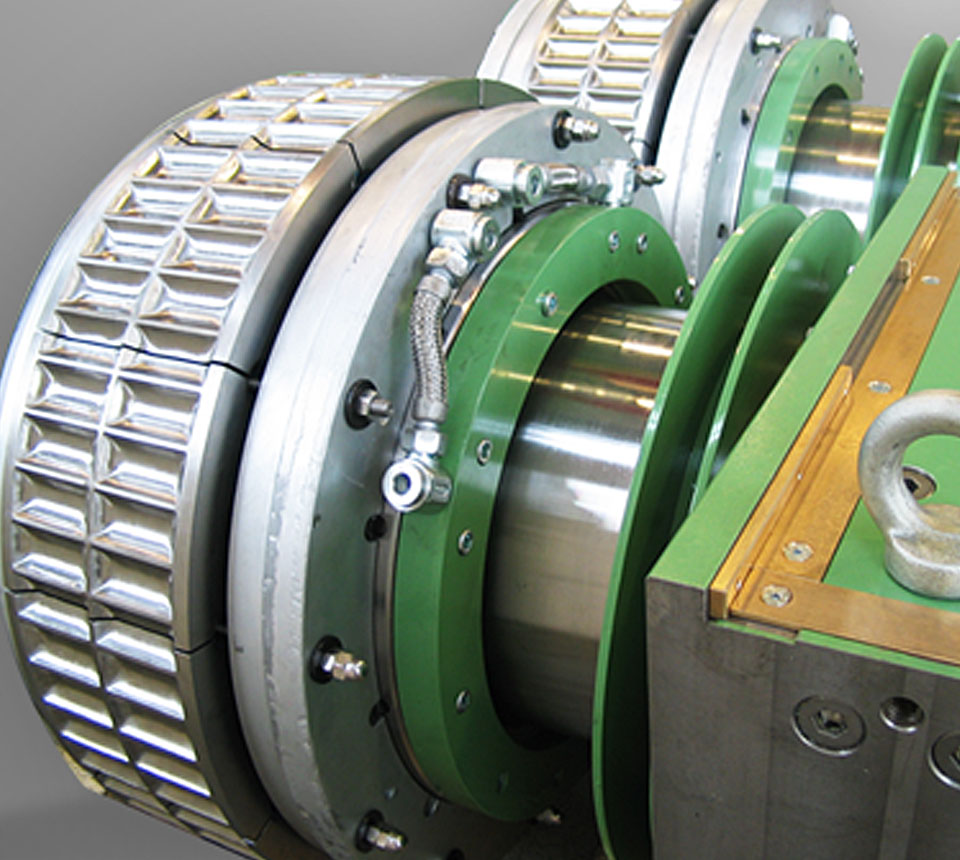

Briquetting Rollers Maintenance

Disassembly, evaluation, maintenance and assembly of:

Rotary union

Zapex coupling

Rowlock and bearings

Clamping rings

Segments

Pins and cotters

Measurement, clearance control and specified tolerance.

Hydrostatic test.

Hot tensioning torque.

Painting, identification and transportation to the client facilities.

Electrochemical Machining

The electrochemical machining (ECM) applies the electrolysis principle for metal removal. The high speed of the electrolyte between the tool and the workpiece, drag the metal ions that come off as a result of anodic dissolution. Allowing the machining of hard materials and get burr-free surfaces, fissures and cracks.

Test Bench for Hydraulic Motors

Supported on our hydraulic testing technology and equipments, we perform measurements in simulated working conditions, equivalent to what the motor will have in real operation.

The unique design of this test bench has advantages that make it stand out over the market such as:

- Motor speed can be adjusted electronically from 0 to 180 rpm during the test.

- Allows automatic control of the motor in both directions (clockwise and counterclockwise).

- Electronic turbine flowmeters measure in real time the engine oil under evaluation.

- With electronic pressure transmitters, we can constantly monitor the readings in the output and pre-load lines of the pump.

- Testing is performed in two phases, with load and without load. In both cases, the engine is operated at different speeds, measuring in each test the oil flow values and pressure.

- Our test bench has a PLC and its control screen allows running and registering all real-time variables.

- The versatility of our test bench ensures our customers that the motor installed in the field will give the expected performance.